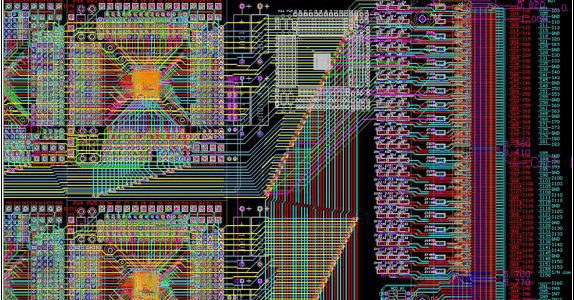

Innovative Circuits Engineering, Inc. offers turnkey services for Printed Circuit Boards: PCB Design, Fabrication, PCB Assembly and Testing. With our experienced team of designers, we design for all applications. Using leading edge design software we can provide quick turn- times, maximum densities with fine mil pitch designs, impedance matching and multi-layer boards with self–check capabilities for Quality Assurance.

Types of Boards:

- Burn-in Boards for All Systems (Including High-Power BIB’s)

- HAST Boards

- Cycling Boards

- Demo Boards

- ESD Test Fixtures

- Program Cards / Modules

- Test Fixtures for Failure Analysis

- Test Adapters for Bench Setups

- System Backplanes

- Special Application Boards

Innovative Circuits Engineering, Inc. can help you with all your PCB needs – from design to assembly and testing. Our team of experienced designers uses the latest software to create high-density, fine mil pitch designs with impedance matching, self–check capabilities and more. We are dedicated to providing prompt service times while meeting the highest standards in quality assurance and customer satisfaction.

PCB Assembly

Our PCB Assembly services include full turnkey assembly of components onto boards – either through hard wiring or surface mount technology (SMT). With SMT, components are placed on top side of the board before being soldered by machine or hand for secure placement. Through-hole technology (THT) is then used when components need to be soldered through a contact in the board from behind.

Quality Assurance

For Quality Assurance purposes, we utilize state-of-the-art testing methods during assembly that include J-STD test coupons (functional checks with electrical continuity test), dynamic optical inspection (to ensure proper component orientation), automated optical inspection (AOI) for post reflow solder joints and X-ray inspections for BGAs (Ball Grid Arrays). Once our finished assembled boards pass rigorous tests, they are ready for delivery!

For those who require further advanced testing options, we offer additional services that range from static electrical testing to burn in/life cycle testing. With burn in/life cycle testing, boards are heated up over a period of time while voltage is applied between power and ground circuits; this tests the product’s performance over long-term usage scenarios and helps detect any potential failures arising during regular use.

Innovative Circuits Engineering is committed to providing our customers with comprehensive PCB solutions tailored to their individual needs – from design through assembly and extreme stress testing if required! Get in touch today for your custom PCB solution!